Deventer: security for system suppliers and metal constructors

Gaskets: important thermal conductivity value for aluminium windows / Discussion about validity / Material density also in focus / Fraunhofer Institute confirms Deventer’s values / Foamed sealing profiles with good thermal insulation / Permanently dimensionally stable / Tailored TPE solutions / Contribution towards sustainability

Leinfelden-Echterdingen – The thermal conductivity value of gaskets plays a major role when calculating the Uw value of aluminium windows and the associated CE declaration. System suppliers usually take the information required for this from tables whose values are based on standardised material samples. Market participants have been discussing their crucial validity for around a year now. These discussions relate to the effect of the density of foamed materials. Deventer, a specialist in sealing profiles made from thermoplastic elastomers (TPE), has picked up on this topical issue.

Read more

“Our values were and still are valid,” assures Managing Director Mike Piqeur. Following customer requests, special tests commissioned at the Fraunhofer Institute have confirmed this once again. Reliable values are only possible when goods samples come directly from production. It must be guaranteed that the material properties of the gaskets match the tested properties exactly. Deventer, as a member of the Roto Window and Door Technology Division (FTT), considers this to be “a matter of course”.

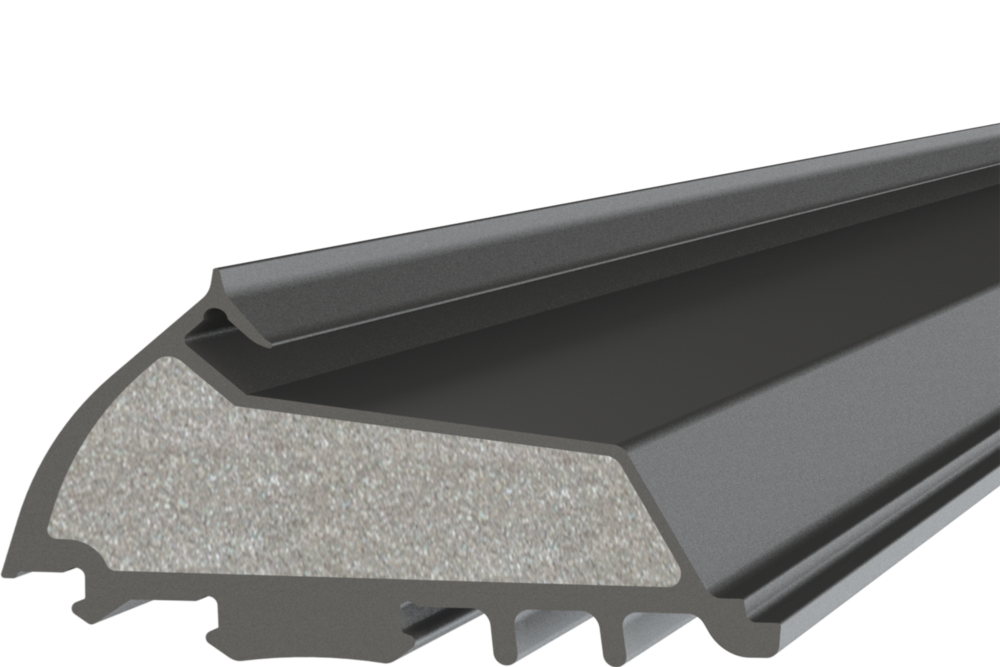

In general, a gasket has to be flexible, robust and highly insulating at the same time. However, this requires the right raw material to be selected and the gasket to foam in the best possible way. The usual density of foamed areas is between 0.6 and 0.75. With the highly resilient and durable profiles from our own range, a value of 0.6 is achieved on a regular basis. According to proof from the Fraunhofer Institute, TPE usually achieves much lower, i.e. better, thermal conductivity values than other conventional raw materials of the same density.

Piqeur decisively rules out practical utilisation of foam sealing profiles with a density of less than 0.6. When foaming, you always reach the point when the gasket loses its shape. However, this is precisely what must not happen. By the same token, exceeding a certain material density is also detrimental for the thermal insulation effect. Thanks to its many years of experience in producing TPE gaskets, Deventer is always able to offer customers tailored solutions with valid thermal conductivity values. “In this way, we can ensure that system suppliers and metal constructors are on the safe side,” highlights the managing director.

Another benefit of the TPE range is also becoming increasing popular on the market: the possibility of separating the gaskets from aluminium without leaving any residue behind. This supports the industry’s systematic recycling efforts. For Piqeur, this is a crucial component in a coherent sustainability concept.