Roto Kalsdorf sets standards in toolmaking

“Excellence in Production” competition / Winner in the category of “Internal toolmaking with fewer than 50 employees” / Reuse concept for tool components / Digital tool logbook / Production process 4.0 / Investment in state-of-the-art technologies

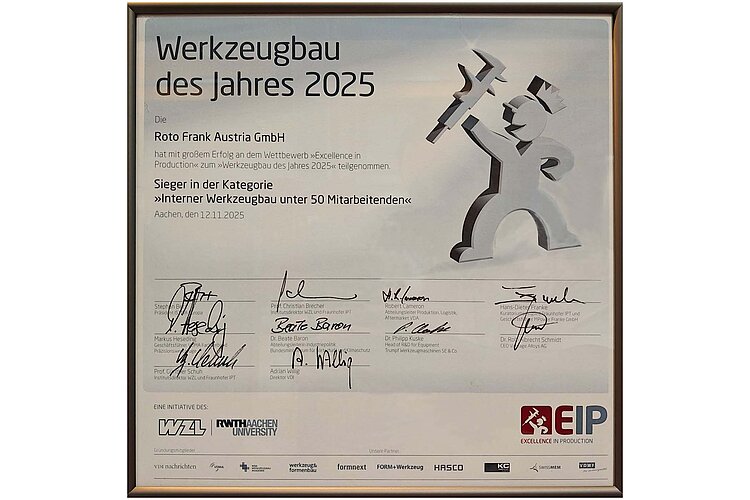

Kalsdorf / Leinfelden-Echterdingen – On 12th November of this year, Roto Frank Austria GmbH, based in Kalsdorf near Graz, was named the winner in the category of “Internal toolmaking with fewer than 50 employees” as part of the prestigious “Excellence in Production” competition. This is testament to how the company is setting standards in digitally interlinked and future-oriented toolmaking. Kalsdorf is one of a total of 18 production plants operated by Roto Frank Fenster- und Türtechnologie GmbH.

Read more

Guided by the principle of long-term added value

What impressed the judging panel most was the systematic reuse concept for tool components at Kalsdorf. This looks at the environmental and economical benefits of reusing tool components and assemblies. Using a digital tool logbook means that every step in the tool life cycle is documented and tracked. This creates ultimate transparency – from production and use through to reuse of individual components.

Quality through digitalisation and full automation

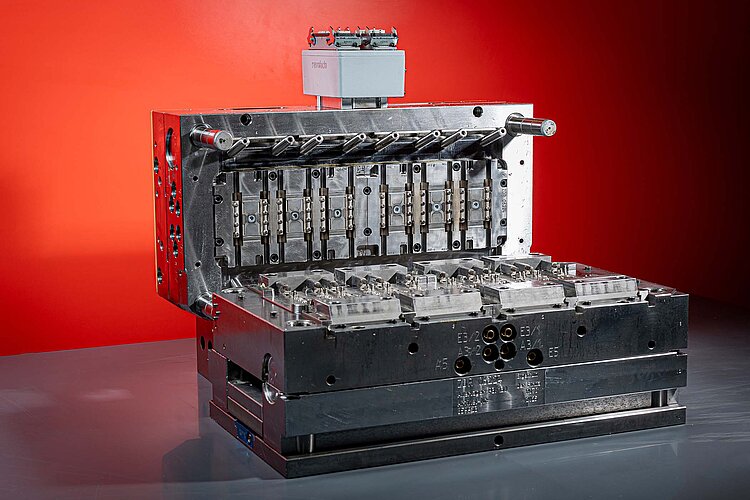

In the Toolmaking department at Kalsdorf, around 30 members of staff produce die-casting, injection moulding and cropping tools for Roto Window and Door Technology’s entire production network. Managing Director Christian Lazarevic emphasises: “Ultra-precise tools in an efficient production process 4.0 can be relied on to achieve the best hardware quality.” This approach embodies the systematic use of state-of-the-art, digitally interlinked technologies in production. These include fully automated machining centres, the digital acquisition and analysis of process data in real time, intelligent control and monitoring of production steps, as well as flexible adaptation to changing requirements.

This makes it possible to deploy resources in the best possible way, detect errors early on and safeguard quality on an ongoing basis. The plant in Kalsdorf boasts impressive vertical integration within Roto Window and Door Technology’s network of plants. The Austrian site produces the majority of the Roto door locks supplied worldwide.

Investment in process optimisation

The latest investments include a fully automated machining centre, taking the production of custom tool components to the next level. Measures for digitised process data acquisition are also being taken so that production processes can be continuously optimised. These investments also help to conserve resources and boost efficiency.

Versatile and quick

In addition to the award-winning Toolmaking department, the Austrian site is also home to hardware and door lock assembly, cropping, electroplating, powder coating, zinc die-casting and PVC injection moulding. This puts the company in the best possible position for the pre-production and custom production of special parts and ultra-small series. “With our toolmakers, in-house die and mould making facilities, and our state-of-the-art systems technology, we are also able to produce prototypes in a short space of time,” states Lazarevic.

Pioneering role in the German-speaking region

This year marked the 22nd time that the “Excellence in Production” award (www.excellence-in-production.de) was presented by the Laboratory for Machine Tools and Production Engineering at RWTH Aachen University and the Fraunhofer Institute for Production Technology. It is considered one of the most prestigious accolades for die and mould making companies in the German-speaking region. More than 200 businesses signed up to be considered in four categories. Winning the category not only sets Roto Frank Austria GmbH apart as a flagship business in the Austrian industry, it is also recognition of its innovation and quality in toolmaking.

Dedicated teamwork is the key element in the consistently high quality of toolmaking at Kalsdorf, and is the main reason behind the win in the competition, as Thomas Hirschmann, Main Process Manager for Semi-Finished Goods Manufacturing, highlights: “The success in the EiP competition is resounding proof of the exceptional work accomplished by our Toolmaking team. It shows how much strength is created when different areas of expertise are combined, and when we work together to achieve a shared goal. Our colleagues impressed with their dedication, wealth of ideas and precision. We’re proud of this achievement and the team spirit behind it.”