“Finger on the pulse” - FTR Fenster- und Türenwerk Rösler, Germany

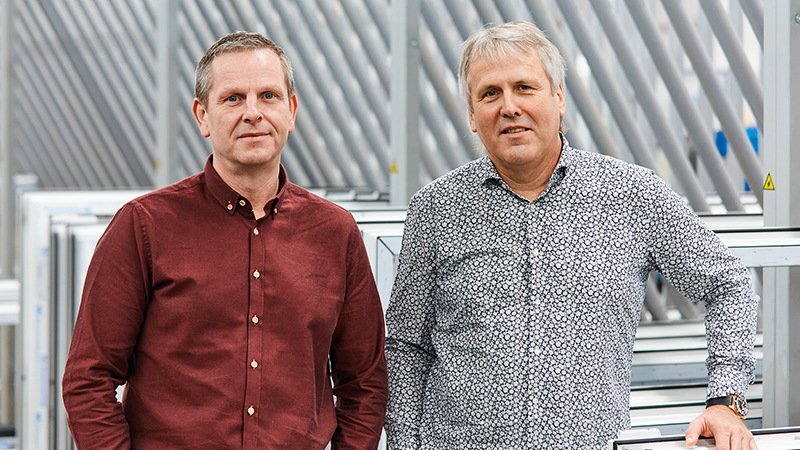

Modern building elements with reliable high quality, efficient production and all accessories promptly installed. That is how owner Thomas Rösler summarises the promise that FTR Fenster- und Türenwerk Rösler GmbH makes to its customers.

Thomas Rösler, who founded the company more than 30 years ago in Schirgiswalde in Saxony, Germany, is convinced that the future of the industry will be shaped by qualified experts supported by automation in production and digitalisation of company processes. “Technology that makes things easier,” he states, is available in manifold forms. However, it needs to be used intelligently.

Roto Lean

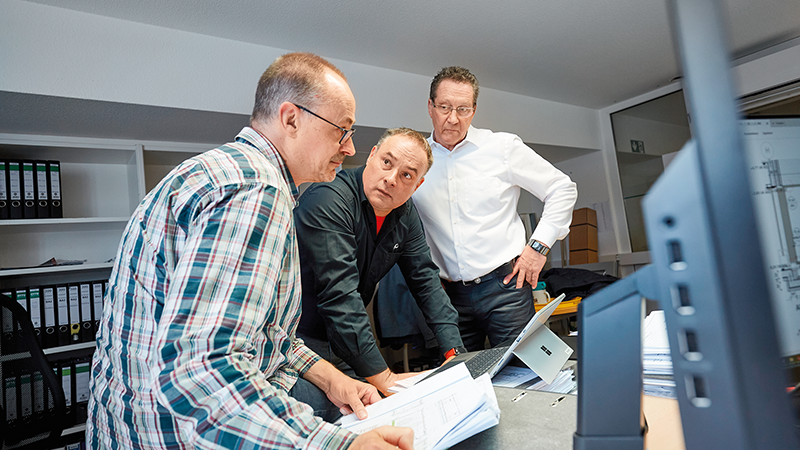

For around ten years, he has been supported by Matthias Bellstedt, who is part of the Roto Lean Team, for questions regarding process development. “Fundamentally, our decision to use Roto hardware when we founded the company has indirectly helped to shape how we work today,” the businessman recalls. He has also frequently discussed the technological future of window production with his contacts in the Sales department of his partner. What might sometimes have sounded a little utopian has now become reality: optimized processes which ensure that people and technology ideally complement each other.

Entirely from a single source

In 2023, FTR achieved turnover of more than 40 million euros. It has loyal customers particularly among general contractors and construction companies. “We are valued as a full-range supplier. All services regarding windows and doors, including installation and maintenance, from one provider. We also supply sun protection and fall protection at the same time.”

The planners and site managers at FTR maintain constant contact with their customers. This enables them to respond flexibly to the progress of construction processes. Thomas Rösler and his Co-Managing Director Enrico Gaens are always available to contact. Gaens emphasises:

“Reliable quality, price and delivery are crucial.”

In the project business, it is vital for manufacturers to specialise, as the business is very demanding and the company ultimately shares in the economic risks of its customers to an extent.

The Roto NX safety factor

FTR’s decades-long partnership with Roto has “covered our back”, Rösler adds.

“In our view, Roto NX is unrivalled.”

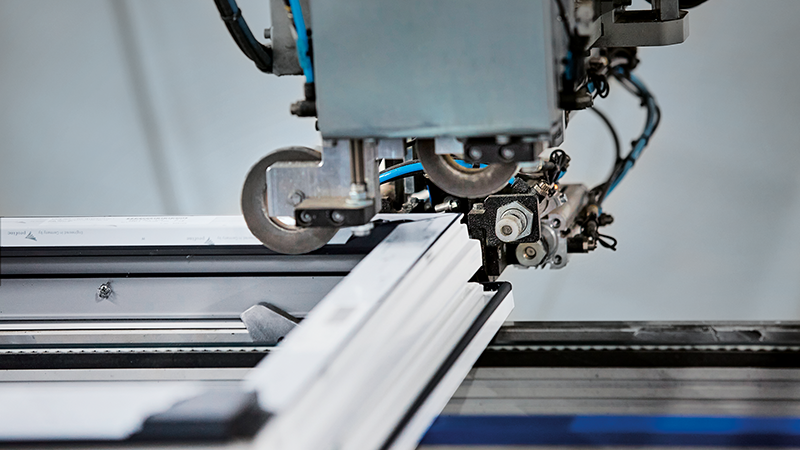

The Tilt&Turn hardware is an important safety factor, just like its predecessor. “We need hardware with reliable quality in the long term, so that we can minimise maintenance and therefore operate economically in the project business.” The commissioning of a new machining centre in Summer 2019 was a crucial factor in FTR being one of the first manufacturers in Germany to want to change over to the Roto NX and thereby enjoy the benefits of automated manufacturing. “We always rely on the latest technology from our partners and try to introduce it as quickly as possible, since that is usually very clearly beneficial to us.”

Economical production of main doors

FTR has regularly used the Solid B main door hinges that Roto introduced at the middle of the last year and the Roto Safe A | Tandeo automatic lock since autumn 2023. “Thanks to the design features of these products that make them easy to install, we save time in the factory and on the construction site. These two advantages provide a double benefit for our business.” FTR equips PVC doors with the 3-part butt hinge 318, and timber doors with the 3-part butt hinge 322. These are also drilled completely via the machining centre.

For manufacturing timber windows, FTR works with Roto hardware as well as with Deventer gaskets and Roto glazing methods. “Excellent quality, produced and delivered by one of our key business partners – this saves us time and hassle,” Rösler states, giving his reasons for concentrating on a small number of suppliers.

Proactive and crisis-proof

Does the current downturn in the home construction sector worry him? “No,” Rösler states firmly, shaking his head. “We have always acted as is prudent for a proper businessman. We are therefore in a healthy economic position and can continue to invest in everything that will help us adapt to new circumstances.” In 2021, he installed a large photovoltaic system with a 674 kilowatt peak on the roofs of the production halls. The vehicle fleet is currently being modernised to reduce consumption of expensive fuel. The FTR team, which includes a great number of employees with many years of experience, always tries to keep their “finger on the pulse” of the industry and respond quickly and decisively.

Digitalisation is a major talking point

Later this year, the company will take the next major step in terms of digitalisation. Continuous data and document management will make it even easier to constantly monitor the efficiency of the entire process. Providing each employee with the information that is important for them and then immediately collating all of the data required for controlling at the end will become much quicker and more reliable thanks to the new IT structure. Rösler emphasises:

“And Roto is important for the development of the company once again.”

The Roto data service and its expert personnel know exactly how to support and effectively reduce the strain on the IT staff at FTR.

Improving stability further

Since the founding of the company, he and his wife have consistently invested their profits in the firm. As a result, FTR is now able to flexibly deploy their specialist employees, trained inhouse, wherever is economically beneficial within its extensively automated production facilities. “We remain a family-owned company in which each employee is important and valued,” emphasises the businessman in conclusion. “We want to further improve our stability, for the benefit of all of our employees and customers. Growth at any price is not what we are about.”

This article was published in Roto Inside 55.