Order safely and know more through digital data exchange

Roto supports window manufacturers in the changeover to EDI / Electronic ordering process saves time and avoids errors / Digitalisation at window manufacturers “picks up speed” / Roto customer portal makes delivery information digitally accessible

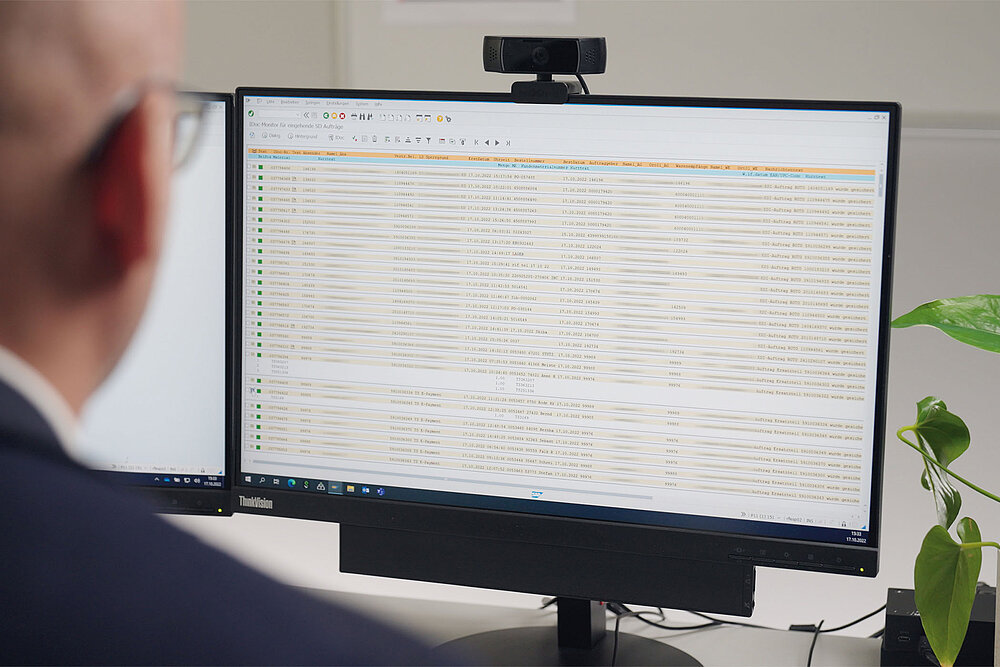

Leinfelden-Echterdingen – “What is already standard between hardware dealers, some industrial window manufacturers and Roto, is currently also on the agenda of many smaller companies that are dealing with the digitalisation of their processes,” reports Petr Jehlicka, Head of Customer and Market Logistics. The topic in question is Electronic Data Interchange (EDI), the electronic exchange of data for orders, delivery notifications and invoices.

Leggi tutto

Manufacturers recognise the opportunities

Ordering and paying via the Internet have long since become standard in people's daily lives. “For years now, private individuals dealing with modern online shops have found that the system points out possible errors in the order and actually asks for all relevant information about dimensions, colours and other design features.” As a result, users are grateful for the certainty that they have ordered the right thing and for the e-mail that usually informs them about the delivery date a short time later. “Ordering electronically from important partners makes much more sense for window manufacturers than online shopping.” Petr Jehlicka, in his summary of the system’s advantages, explains that this is because EDI gives all parties involved the opportunity to respond quickly or even in real time and guarantees error-free data exchange.

Around 40% of all order items worldwide are now sent to Roto electronically and are automatically processed by the system, avoiding the need for employees to spend considerable time checking and entering orders themselves. “This is economical for both sides and shortens the processing time and, therefore, the delivery time.”

Full benefit

According to Petr Jehlicka, the scope of the digital services is coordinated and implemented with each customer on an individual basis. Roto partners generally have two options for electronic data exchange: either they can transmit their orders via what is known as the Mail2EDI process, whereby they use and send an SAP-compatible order form. Alternatively, they handle the entire process, right through to invoicing, fully automatically in the EDI procedure. In this “full stage” process, all documentation is exchanged electronically – namely the order confirmation, delivery notification, invoicing and, if desired, any other important documents that have been mutually agreed upon beforehand. Of course, the hardware specialist offers advice to interested parties worldwide on how to get started with the EDI process and provides support to its customers during the implementation phase.

Self-service

The EDI service is soon to be integrated into a Roto customer portal, which, among many other features, will provide additional benefits for tracking the order process: window manufacturers and hardware dealers log in via the Internet to receive information on previous orders, delivery statuses or invoices, for example. “The new customer portal therefore offers even greater transparency and security thanks to information on current and planned orders that is updated on a daily basis,” says Jehlicka about the portal. His conclusion is that window manufacturers who have not yet engaged with electronic ordering should do so as soon as possible. “The industry is becoming ever more digital, and electronic exchange with service-oriented partners like Roto saves time, offers greater security and is indispensable for everyone who wants to increase efficiency in their company.”