Fensterbau Frontale 2024: The one for everything

“Roto NX” at “Fensterbau Frontale” / “Roto City” is brought to life: Tilt&Turn elements in all frame materials for every building type / Eight hinge sides for all Tilt&Turn window requirements / Using many of the same parts / Added value for the utilisation of rooms / Up to RC 4 / Quality from the global market leader for Tilt&Turn hardware / Hardware and seal optimally coordinated

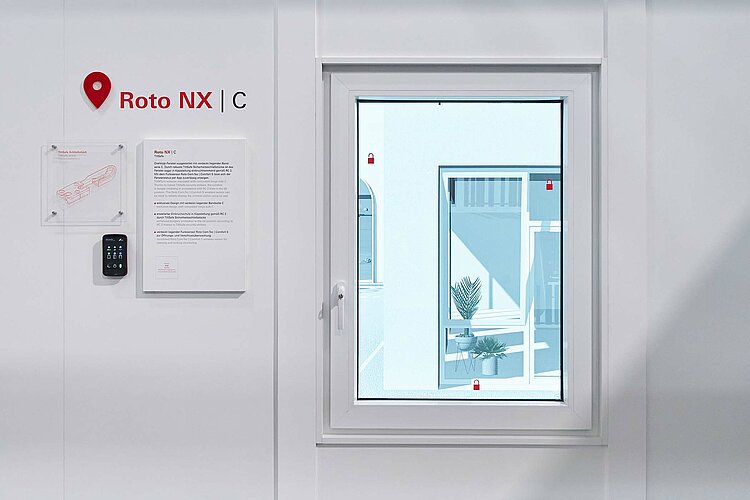

Leinfelden-Echterdingen – It will soon be 90 years since Roto founder Wilhelm Frank designed the first Tilt&Turn hardware to be industrially produced. By doing so, he established a company that would grow to become the global market leader for Tilt&Turn hardware – a position that it has managed to hold on to for decades through innovations and consistently high product quality. The Tilt&Turn product range from Roto Frank Fenster- und Türtechnologie GmbH, which is currently dominating the market, is trusted by manufacturers, regardless of whether their windows are made from PVC, timber or aluminium. No matter whether the hinge side is surface-mounted or concealed – “Roto NX” helps ensure economical and flexible production of Tilt&Turn elements in all formats and forms for rooms in private and public buildings. At “Fensterbau Frontale”, numerous exhibits in the ”Roto City” proved this once again.

Leggi tutto

Efficient production with the same parts

One of the main characterising features of the “Roto NX” hardware product range is that many of the same parts are used. This reduces the number of different components that have to be purchased and stored by the Production Logistics department. At the same time, the product range, which the manufacturer also describes as a “modular” stands out thanks to its huge breadth. Many components for greater security and comfort when using Tilt&Turn elements are only available from Roto.

The benefits of this “modular” principle becomes especially apparent when manufacturers produce Tilt&Turn windows made from PVC and aluminium profiles with a 16 mm hardware groove, among other applications. They enjoy the economic benefits of extremely streamlined stock levels. This is because the “Roto NX | A16” hinge side for aluminium profiles is the same as the “Roto NX | P” hinge side for PVC windows, save for a few components. Most of the other hardware components can also be used for both frame materials.

Hinge sides for every frame material

With eight different hinge sides, “Roto NX” makes it possible to flexibly meet all Tilt&Turn window requirements with regard to the variety of formats, weights and designs. All hinge sides have been designed so that they can be processed both manually or partly or fully automatically and are easy to adjust. There is a wide selection of attractive surfaces and colours for all visible components.

Hinge side innovations

The “Roto NX | A16” hinge side is tested for aluminium windows up to a sash weight of 150 kg and is also suitable for round and pitched windows, as well as for balcony doors with a threshold. The “Roto NX | C” hinge side supports PVC or timber sashes in various formats up to a maximum sash rebate width of 1750 mm and a maximum sash rebate height of 3000 mm. Extremely slim, ceiling-height windows, which are currently very popular, can also be created. The high functional safety of this further developed “Roto NX” hinge side has been proved by durability class H3 tests in accordance with DIN EN 13126-8 (20,000 cycles). Roto offers a ten-year performance warranty for both hinge sides.

Safe operation of heavy sashes

Timber construction material and its natural beauty are now more popular than ever. The same is true of large windows. With the “Roto NX | Power Hinge” hinge side, Roto ensures security and long-lasting quality for heavy sashes. It can be used on Tilt&Turn windows up to a sash weight of 200 kg and on Turn-Only windows up to a sash weight of 300 kg. P and V cams are available for producing burglar inhibiting windows and balcony doors.

Anti-slam device also for retrofitting

Extremely heavy Tilt&Turn sashes may close inadvertently if their centre of mass is more than 33 mm above the sash overlap. This is why an anti-slam device is also available for use with the “Roto NX | Power Hinge” hinge side. It secures the sash in the tilt position and can be flexibly retrofitted at any time.

Tilt before turn

The “TiltFirst” variant of “Roto NX” has proved its worth as a “tilt before turn” opening version in many public buildings. When the handle is locked, the window sash can still be tilted but cannot be turned open fully. This helps protect specific groups of people and users of the room, e.g. in hotels, schools, nurseries or retirement homes. Many Roto customers also recommend “TiltFirst” for children’s rooms. On request, “TiltFirst” can also be combined with “TiltSafe”, the Roto security technology for greater burglary protection.

Burglary protection up to RC 4

Even in the standard version, “Roto NX” with circumferential locking points provides impressive mechanical burglary protection. Security components like the “TiltSafe” security strikers for the tilt position improve burglary protection without compromising on comfort. At present, the Tilt&Turn modular hardware system from Roto is the only solution that is able to offer tested security in accordance with RC 2, even when the window is tilted. But that’s not all this range is capable of: specialist window manufacturers have already produced elements with “Roto NX”, which have passed tests in accordance with RC 4 and have been installed in buildings with strict security requirements.

Optimal coordination of hardware and seal

Window manufacturers around the world are not only able to purchase hardware technology from Roto, but sealing profiles too. The manufacturer speaks of a “perfect match” for tight sealing and long-lasting operating convenience. On request, the sealing profiles can be optimally coordinated with the kinematics of a Tilt&Turn window, for example, and the specific “Roto NX” hardware configuration that is selected, and are produced to meet the customer’s individual requirements. The Group’s specialist advisers and test laboratories provide support to window manufacturers, even as early as during the product development process. Roto guarantees ultimate delivery reliability for all hardware components and sealing profiles.

At seven sites across the European and American continents, subsidiaries Deventer and Ultrafab produce sealing profiles for customers of the Roto Group and for industrial companies from other sectors. Both companies have vast expertise in the processing of different synthetic materials. The sealing profiles they produce can be processed extremely efficiently and the raw materials used can be recycled. This means that the product ranges of both seal specialists meet the market’s demands for resource-conserving solutions.

Added value for rooms and buildings

Depending on the building type and how the room is used, window hardware from Roto can play an important role in boosting comfort and security. With their guaranteed functional safety and tested quality, they increase the practical value, simplify maintenance and improve the durability of buildings. Sustainable construction requires premium building elements with reliable hardware technology, just like those that are available from Roto and were showcased in the “Roto City” at “Fensterbau Frontale”.

On display here were Tilt&Turn elements made from all frame materials with a hardware configuration which can create added value for users regardless of the building type. All of the exhibits have also been integrated into the “Roto City”. This means that anyone interested in the hardware configurations presented at the trade show can take a closer look at them at any time. Visitors to the “Roto City”, a virtual conference and exhibition centre, are accompanied by their assigned regional specialist advisor from Roto Sales.