Production efficiency and automation

In economically challenging times, efficiency in production plays an important role in a window manufacturer’s success. Various factors determine whether new tools, a machining centre or an automatic hardware machine will actually improve efficiency.

Andreas Eberts, Head of Roto Lean Management and the Data Service at Roto Frank FTT Vertriebs-GmbH, describes what manufacturers must consider, in his experience, before investing in automation.

Roto Inside: Mr Eberts, what should window manufacturers bear in mind if they are considering automation?

Andreas Eberts: It’s important first of all to take a good look at how processes within the company should be structured to obtain maximum benefits from an additional automation step. For example, if new systems are being procured, that’s a good opportunity to implement other sensible optimisation measures. Ultimately what matters is establishing new, reliable processes and achieving high production quality. There are many different factors when it comes to making production more efficient while improving employee satisfaction.

Roto Inside: In your opinion, when does it make sense to use machining centres and automatic hardware machines?

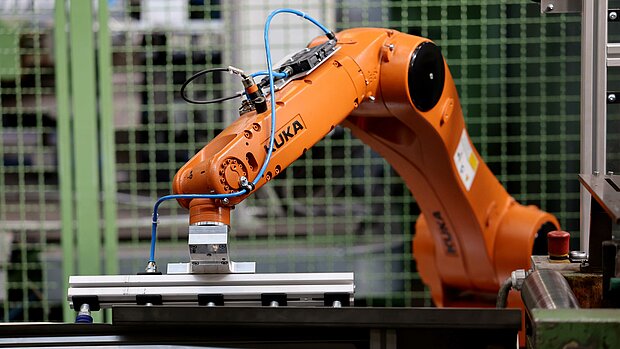

Andreas Eberts: It makes sense to use them if they can provide staff with the support they need and reduce their workload. These machines can produce greatly increased volumes and provide better quality assurance. If robots or automatic machines are planned in isolation and the production processes are not optimised alongside them, this will not achieve all of the possible improvements. Often, manufacturers are shocked to learn where new bottlenecks will occur if they don’t also adapt their processes. Something that is unfortunately frequently overlooked is that even quality improvements in article master data management and digital processes can hugely improve efficiency within the company. For instance, this can speed up ordering and internal parts logistics and prevent errors being made. This is why Roto has expanded its data service in recent years. We have received very positive feedback from customers.

Roto Inside: So the machining centre or automatic hardware machine alone do not ensure efficiency, rather the company has to become efficient by organising its production processes in a suitable way?

Andreas Eberts: Exactly. If the processes have been optimised, modern systems will provide real added value. This also applies to small collaborative robots, known as cobots, which can replace routine tasks or physically demanding manual work. We look into many different production technologies for window manufacturers so that we can discuss all conceivable solutions with customers.

Roto Inside: Think about the most recent conversations you had with window manufacturers – what were they about?

Andreas Eberts: The shortage of skills and labour is currently a major issue for a great many companies. This is why the interest in automation is growing hugely right now. If window manufacturers aren’t able to recruit more workers, they have to use every possible means to avoid wasting working time. Sometimes suboptimal in-house transport of goods leads to inefficiency. If staff have to wait on hardware to complete assembly, this is a waste of time and money. The hardware master data is often not used optimally. A continuous flow of information from incoming orders to loading avoids errors and saves money. To put it in a nutshell, what matters is “lean” production. This means avoiding wasting all kinds of resources, improving the flow of materials within the factory, and sharing tasks evenly among employees.

Roto Inside: Does Roto recommend using automatic hardware machines – for Roto NX, for example?

Andreas Eberts: Roto is working on offering as many products as possible for fully automated production. Our Roto NX Tilt&Turn hardware is suitable for manual, semi-automated and fully automated processing. So no matter what measures a company wants to take to make production more efficient – Roto NX will be involved. It is and will remain the best Tilt&Turn hardware for window manufacturers, no matter the size of the company.

This article was published in Roto Inside 54.